Address

Energy Incentives, INC

3517 W. Canal Dr.

Kennewick, WA. 99336

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: Day off

Address

Energy Incentives, INC

3517 W. Canal Dr.

Kennewick, WA. 99336

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: Day off

An air leakage test measures how much air escapes from a building, helping to improve energy efficiency. This guide will explain what an air leakage test is, how it works, its benefits, and when to perform it. For more information on air leakage testing, visit our main guide.

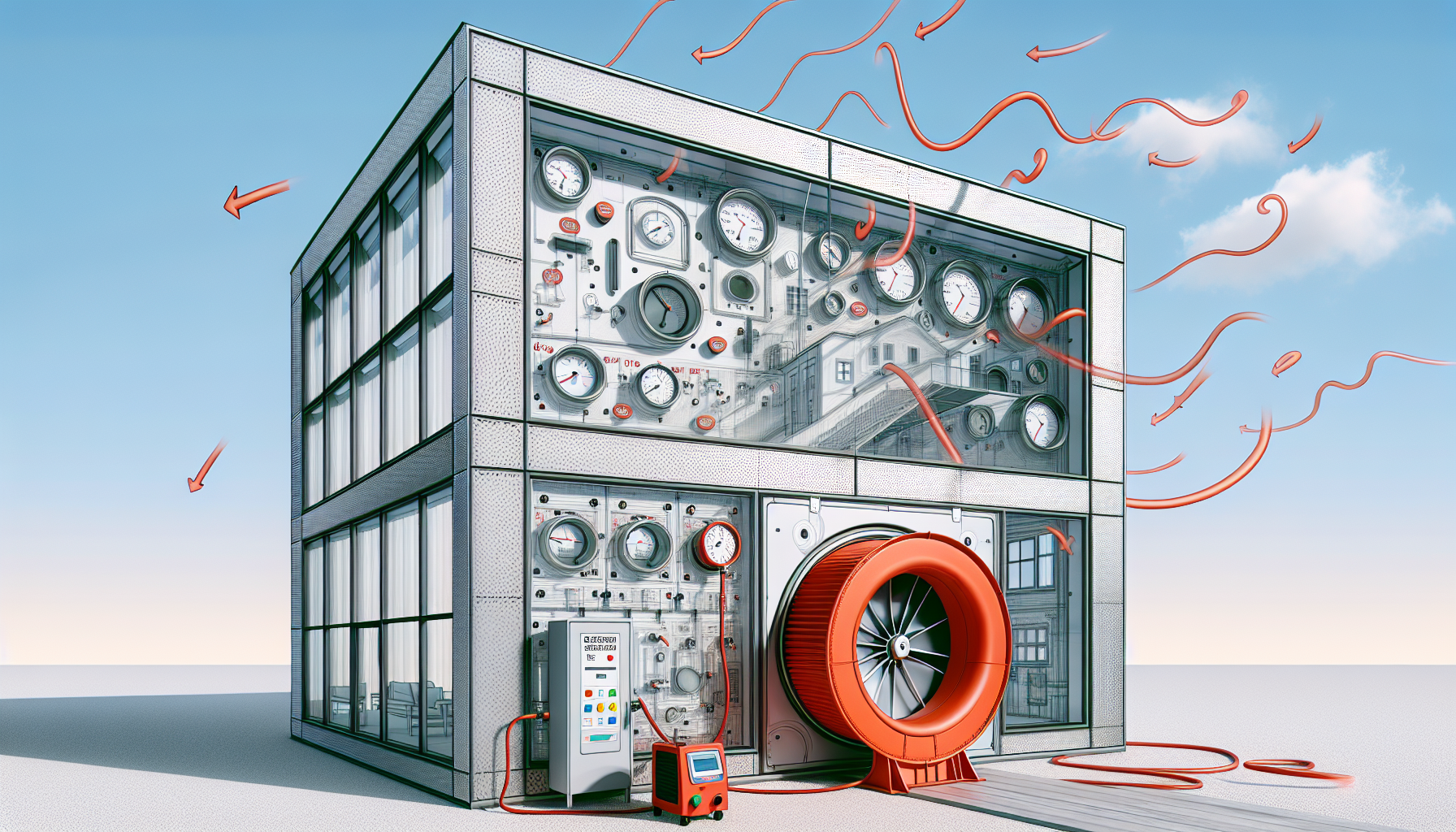

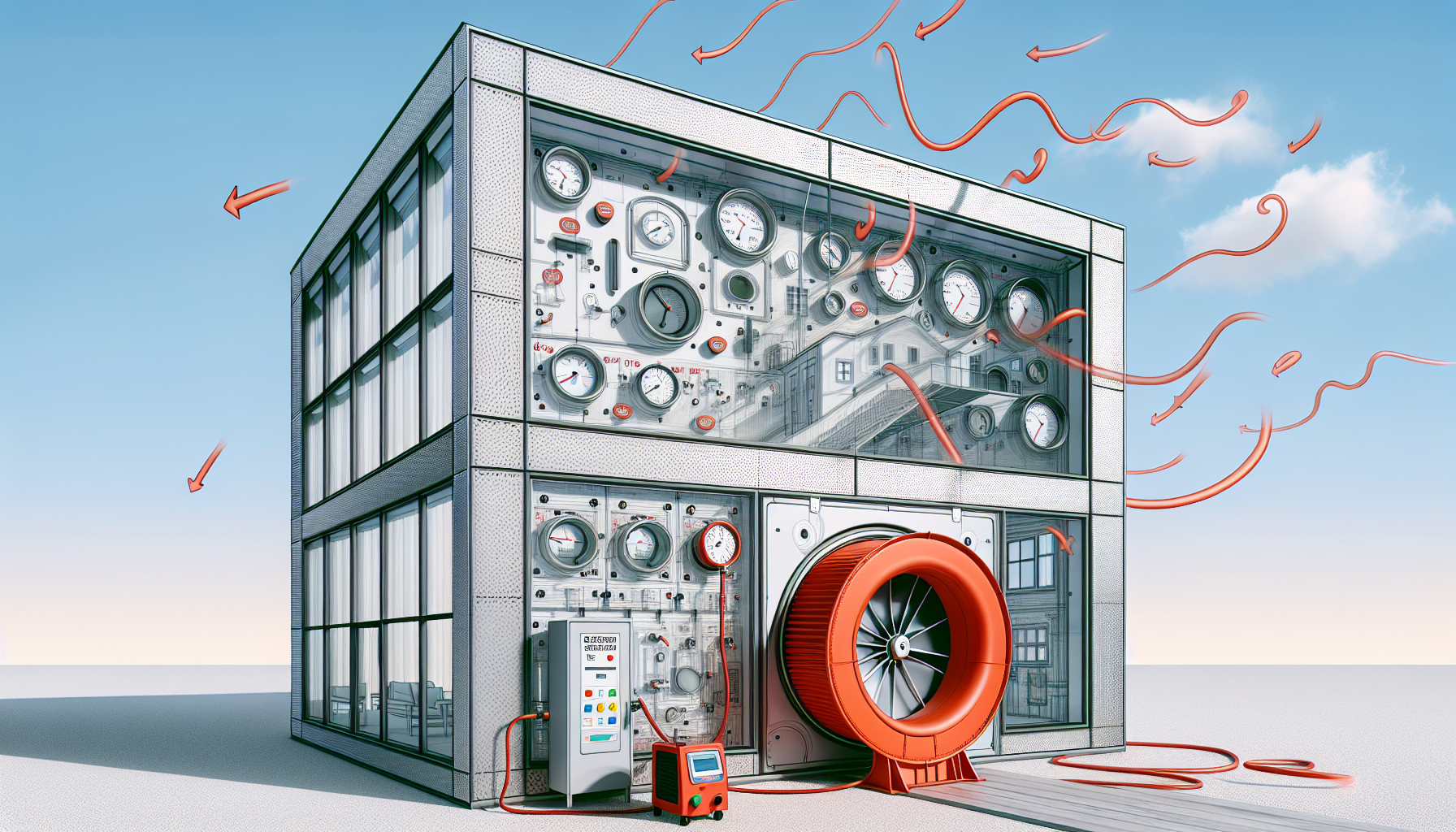

A building air leakage test, also known as air leakage testing, is a method used to measure a building’s airtightness by using a blower fan and pressure gauges. The primary goal is to determine the amount of air leakage in cubic meters per square meter of the building’s internal surface area. This process is also known as a blower door test because the fans are often placed in an open door frame.

Identifying gaps and breaks in the building envelope is a key function of air leakage testing. This testing aids in addressing issues that impact heating and cooling costs. It’s not just about saving money—air leakage testing is crucial for:

Think of it as a comprehensive health check-up for your building’s envelope.

In essence, air leakage testing is part of a broader package of enclosure testing designed to verify the performance of the building envelope. Detecting and sealing drafts, leaks, and gaps is a proactive measure to maintain your building’s energy efficiency and comfort throughout the year.

To conduct an air leakage test, follow these steps:

Pressure gauges and a manometer are used to measure airflow and identify any air leakage or infiltration. During the test, additional diagnostic tools may be used to confirm the collected data. Such tools not only guarantee the accuracy of results but also provide ongoing test data for methods like vacuum decay and pressure decay, offering a comprehensive view of the building’s airtightness.

Conducting an air leakage test offers numerous benefits, including improved energy efficiency, enhanced indoor air quality, and increased occupant comfort. Identifying and addressing air leaks is instrumental in maintaining the energy efficiency of your building, making it a healthier and more comfortable place for living or working.

Let’s delve deeper into these benefits. Top 5 Reasons Every Business Needs a Commercial Air Leakage Test.

An airtight building offers several benefits, including:

By identifying and sealing air leaks, you can achieve these benefits and improve the efficiency of your building air.

Beyond the financial savings, reducing energy consumption also has a positive impact on the environment. Buildings with lower air leakage require less energy, resulting in lower carbon emissions. Reducing the need for excessive heating and cooling through air leakage tests contributes to lower greenhouse gas emissions, promoting environmental friendliness of your building.

Air leakage tests play a vital role in determining the correct airflow and size for HVAC equipment, allowing for more efficient operation. To detect air leaks supports moisture control, reducing risks of mold, mildew, and water damage. This not only enhances the overall performance of the building but also helps maintain its value over time.

Regular air permeability tests are essential for ensuring compliance with building codes and regulations. Addressing air leaks is a crucial step towards enhancing the performance of your building envelope and meeting the required standards for energy efficiency and indoor air quality.

Addressing air leaks can significantly enhance occupant comfort by reducing drafts and temperature fluctuations. This ensures a more consistent and comfortable indoor environment, free from cold spots and uncomfortable drafts. The testing process can also uncover structural vulnerabilities that could lead to moisture buildup and mold growth.

Effective air permeability management ensures that there is enough fresh air to dilute and remove pollutants like VOCs, allergens, and moisture, thereby improving indoor air quality. This not only makes the living or working space more comfortable but also healthier for the occupants.

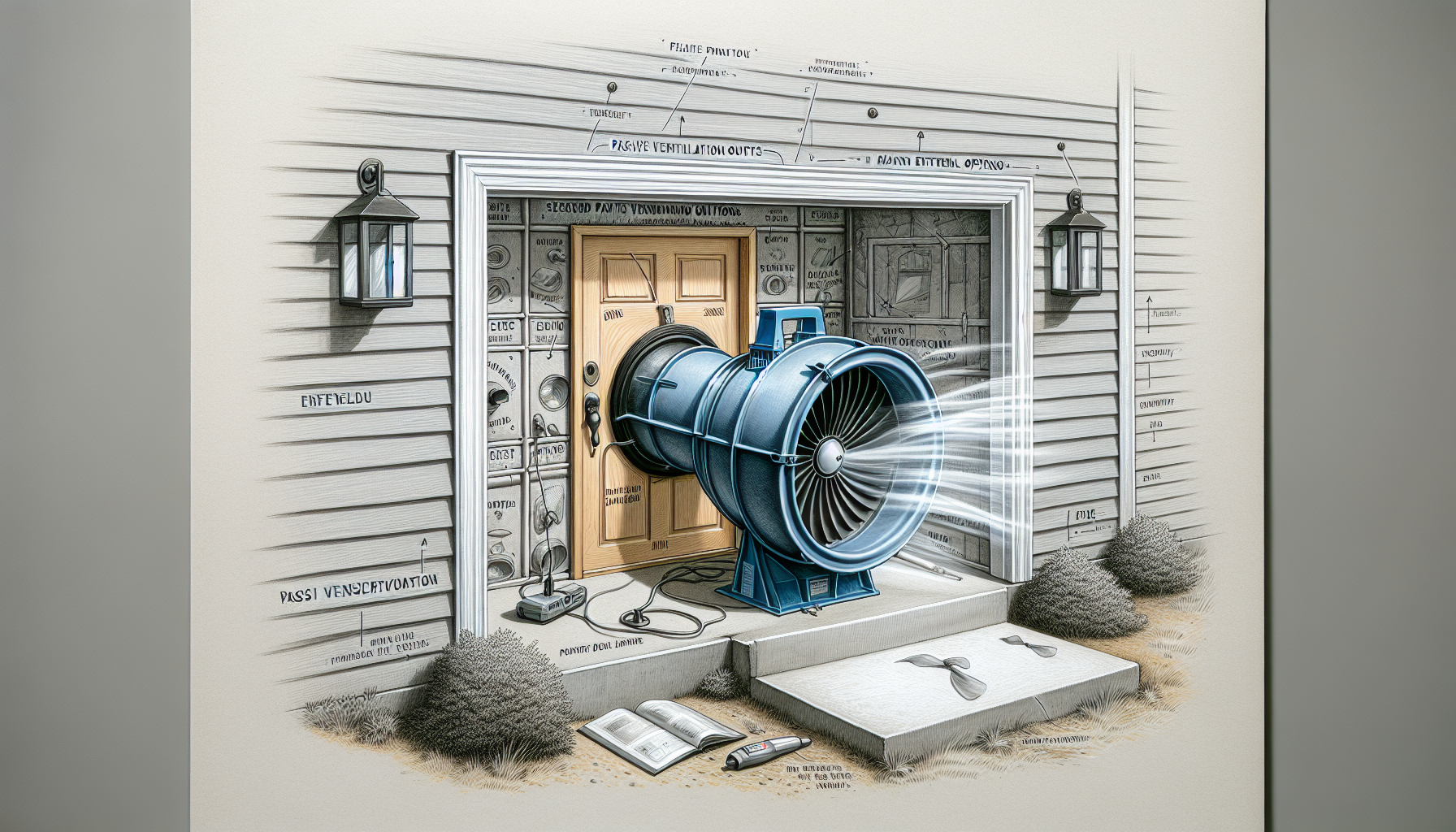

The optimal time to conduct an air leakage test is after all doors, windows, and weather stripping have been installed in the building. This guarantees the completion of the building envelope and the accurate identification of any potential air leaks. It is practical to conduct air leakage testing during new construction projects before installing siding or exterior coverings.

Sealing air leaks is easier before finishes are installed, making mid-construction an ideal time for testing. However, it’s also common to perform air leakage testing after building occupancy to identify and address any issues that may arise over time. Choosing a calm day for the test is advisable, as windy conditions can complicate the process.

Compliance with building regulations often requires air leakage testing, especially for new constructions and renovations. For instance, the 2018 International Residential Code (IRC) mandates air-leakage testing for new residential construction to ensure it meets air change per hour standards. Similarly, Part L of the UK building regulations requires an air tightness test for new builds and non-domestic buildings with over 500m² gross floor area. To achieve compliance, air tightness testing is a crucial step in the process.

Various states in the US, like Pennsylvania, require third-party testing on new construction projects. Testing as a standard has been established by many other states through the adoption of the International Construction Code (ICC) of 2015. This demonstrates a widespread acceptance and implementation of the code across various jurisdictions. These regulations ensure that buildings meet the necessary energy efficiency standards and maintain a high level of performance.

Homeowners and property managers often conduct air leakage tests for the following reasons:

Commercial property owners and tenants also benefit from air leakage tests to maintain optimal indoor conditions and ensure compliance with energy efficiency standards. Air leakage testing is utilized by industrial facilities if they observe problems with indoor air quality or the potential infiltration of external contaminants as indicated by their monitoring devices. This test helps to identify and address any air leakage issues that may be affecting the facility, particularly where air leakage occurs. By conducting air testing, it guarantees the safety and efficiency of the working environment.

The cost of an air leakage test can vary depending on several factors, including labor costs, building complexity, and location. Here are some average costs:

Factors influencing the cost include labor costs for HVAC technicians, which can range from $75 to $150 per hour, and the complexity of the home, as seen in energy audits that can cost between $200 and $680 depending on home complexity. Getting a grasp of these costs aids in budgeting for air leakage testing, ensuring that you get the best value for your investment.

A good air tightness test result is around 5 m³/h·m² or lower, indicating the building meets both carbon emission and fabric energy efficiency targets. A score near 10 suggests the building isn’t efficient enough, while a score just under 5 typically indicates sufficient airtightness to pass the test and meet efficiency standards.

Buildings scoring below 3 on an air tightness test may require mechanical ventilation to prevent issues like dampness and poor air quality. Testing helps discover and log inconsistencies, indicating potential construction flaws and areas for improvement. Comprehending these results is key to maintaining a high-performing, energy-efficient building.

Various tools and techniques are used in air leakage testing, including pressure decay and vacuum decay methods. Compact pressure decay leak testers reduce the connection volume needed for tests, increasing sensitivity and reducing test time. Large display leak testers have greater internal capacity and test volumes, enabling faster testing.

Testing must be conducted and reported in accordance with standards such as RESNET/ICC 380, ASTM E779, or ASTM E1827. Verifying that the service provider uses up-to-date diagnostic tools like built-in pressure gauges and manometers is vital for accurate results and measuring internal pressure.

Selecting an apt air leakage testing service provider is critical for achieving accurate and trustworthy results. Look for providers who can conduct testing as part of a comprehensive energy audit to ensure thorough and accurate results. Providers experienced with new construction projects are better equipped to identify and remediate leaks before exterior siding is installed.

It’s also essential to select a provider that offers third-party testing, which may be required by state regulations. Choosing a reliable and experienced service provider guarantees that your building meets the required standards for energy efficiency and indoor air quality.

In summary, air leakage testing is a vital process for ensuring your building is energy-efficient, comfortable, and compliant with regulations. By understanding the benefits, costs, and results of these tests, you can make informed decisions to improve your building’s performance. Consider conducting an air leakage test to secure both financial savings and environmental benefits.

An air leakage test measures a building’s airtightness by using a blower fan and pressure gauges to detect and quantify air leaks. It helps in identifying areas that need improvement in terms of sealing and insulation.

An air leakage test works by sealing passive ventilation, closing exterior openings, and using a blower fan and pressure gauges to measure airflow and identify leaks. This method helps to assess the airtightness of a building.

An air leakage test should be performed after the building envelope is complete, during new construction projects before installing siding, or as part of a comprehensive energy audit. This ensures accurate results and helps identify any potential issues early on.

The cost of an air leakage test can range from $200 to $750, depending on factors such as labor and building complexity.

Air tightness test results around 5 m³/h·m² or lower indicate sufficient airtightness to meet efficiency standards and prevent issues like dampness and poor air quality. Aim for this level for a good result.